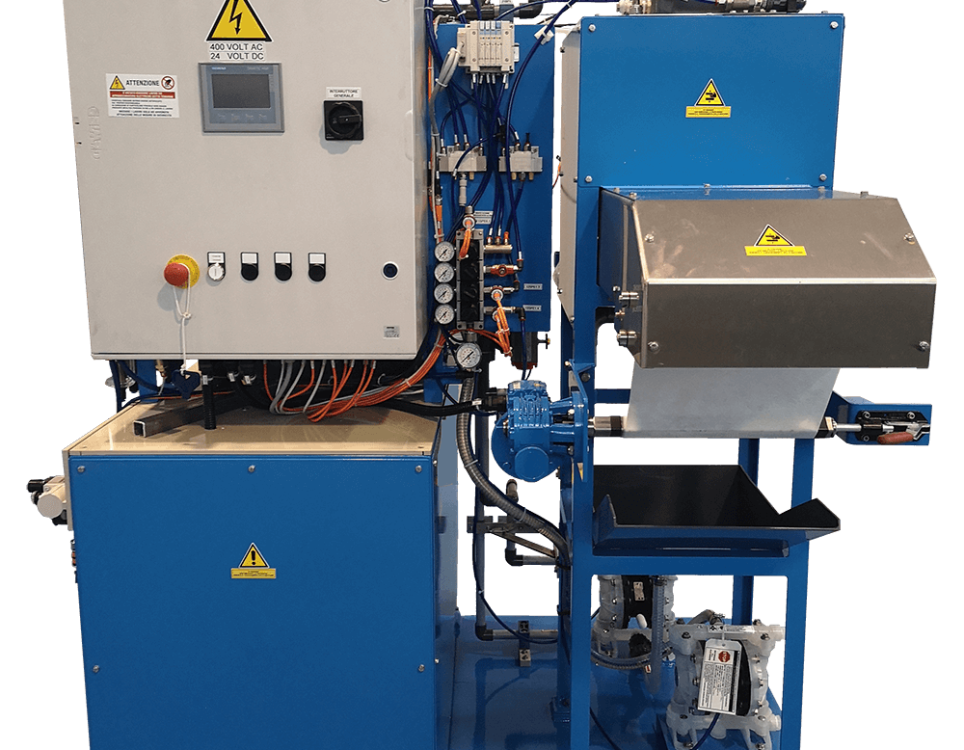

EnvioTECH Raw Material Recovery and Reuse Equipment

Recycling valuable materials, particularly chemical wastes containing metals, has become both cost-effective and technically viable. Metals such as Nickel, Copper, and Chromium can be recovered and reintroduced directly into production, minimizing wastewater treatment and reducing costs.

MacDermid Envio goes beyond standard wastewater treatment to reclaim metals and materials used in manufacturing. Our advanced NiCycle, CuCycle, and HexCycle systems enable leading surface finishing companies to recover and reuse valuable metal salts.

In addition to raw material recovery and reuse equipment, our EnvioTECH portfolio also includes electrolyte conditioning systems as well as advanced solutions for trivalent chromium rinsewater treatment.

EnvioTECH Process Integration

Our tailored EnvioTECH units integrate seamlessly with processes including:

Why partner with MacDermid Envio Solutions?

With over 40 years of experience, MacDermid Envio is a trusted leader in water and material recycling. We provide tailored technology, fully automated systems, and comprehensive solutions—from installation to maintenance and ongoing support. Our solutions ensure maximum efficiency and integrate seamlessly into your existing operations.

Discover the range of innovative solutions offered by MacDermid Envio Solutions below.

CarboPure - Carbonate Removal System

CarboPure efficiently removes carbonates and sulfates from sodium-based alkaline electroplating processes without significant solution loss. By reducing excess carbonates, CarboPure improves cathode efficiency, plating speed, deposit distribution, and chemical consumption while minimizing waste generation. Fully automated, CarboPure ensures continuous operation without production downtime.

CarboPure is ideal for alkaline electrolytes, including Alkaline Zinc, Alkaline Zinc Nickel, Cyanide Copper, Cyanide Bronze, and other highly alkaline solutions.

Features

- Unique air-drying cycle for dewatering carbonate and sulfate solids

- Fully programmable automated solution loading

- Automatic indexing filter

- Automatic defrost cycle

- System washout at shutdown

- EasyConnect option for seamless integration

CarboPure Benefits

NiCycle™ – Nickel Recovery System

NiCycle recovers over 90% of nickel from electroplating rinse waters, significantly reducing costs and waste. The recovered nickel solutions are free of organics and sulfur compounds, making them ideal for reuse in nickel plating processes.

The system works efficiently with various nickel electrolytes, including Wood’s nickel strike, semi-bright nickel, satin nickel, bright nickel, and microporous nickel. Our highly selective ion exchange resin collects, concentrates, and purifies nickel in sulfate or chloride form for immediate reuse. NiCycle also allows batch-to-batch switching between nickel chloride and nickel sulfate production.

NiCycle Features & Benefits

NiCycle is trusted by leading nickel plating and plating-on-plastics companies, with some achieving annual savings exceeding $400,000.

CuCycle™– Copper Recovery System

CuCycle recovers over 90% of copper from sulphate-based electroplating rinse waters, delivering significant cost savings and waste reduction. Our innovative design concentrates copper efficiently, reducing its content in rinse water to less than 2 ppm. This minimizes waste treatment costs and lowers disposal volumes.

Features & Benefits

- Recycles over 90% of copper from rinse waters

- Fully automated copper recovery system

- No upfront equipment investment cost

- Immediate cost savings and return on investment

- Reduces copper salt consumption

- Less dependency on fluctuating copper prices

- Lowers waste treatment costs and sludge generation

- Minimizes environmental footprint

HexCycle™ – Chromic Acid Recovery System

HexCycle recovers up to 99% of chromic acid from chrome etch and hex chrome plating rinse waters, delivering significant cost savings and waste reduction. By concentrating chromic acid waste, HexCycle minimizes wastewater treatment and operational costs. It is the most durable and efficient recovery system available globally for chromic acid etching and decorative chrome plating processes.

HexCycle units evaporate 200-400 liters of rinse water per hour, returning a concentrated solution of up to 250 grams per liter of chromic acid.

Features & Benefits

- Recovers 95-99% of chromic acid from rinse waters

- Immediate cost savings with no upfront equipment investment

- Reduces dependency on material availability

- Lowers sludge generation in wastewater treatment

- Minimizes environmental footprint

EnvioTRI™ – Trivalent Chromium Rinsewater Treatment

EnvioTRI is a fully automated system that simplifies wastewater treatment for trivalent chrome rinses, ensuring compliance with current and upcoming CrVI regulations. Its innovative filtration materials eliminate the need for time- and energy-intensive treatment of trivalent chrome complexes. The minimized CrIII concentrate can be externally treated, while the permeate integrates seamlessly into existing wastewater treatment plants (WWTP).

Features & Benefits

- Treats chloride-, sulfate-based, and hybrid trivalent chrome electrolytes

- Suitable for rack and barrel applications

- Removes up to 99.5% of trivalent chrome

- In-situ waste treatment for efficiency

- Fully automated, autonomous operation

- Future-proof: anticipates upcoming regulations

- Industry 4.0 compliant (EU standards)

- Reduces wastewater treatment costs and ensures consent limit compliance

- Scalable for diverse operational needs