Advanced Wastewater Treatment for Surface Finishing & Electroplating

Effective WWT Solutions for Compliance and Sustainability

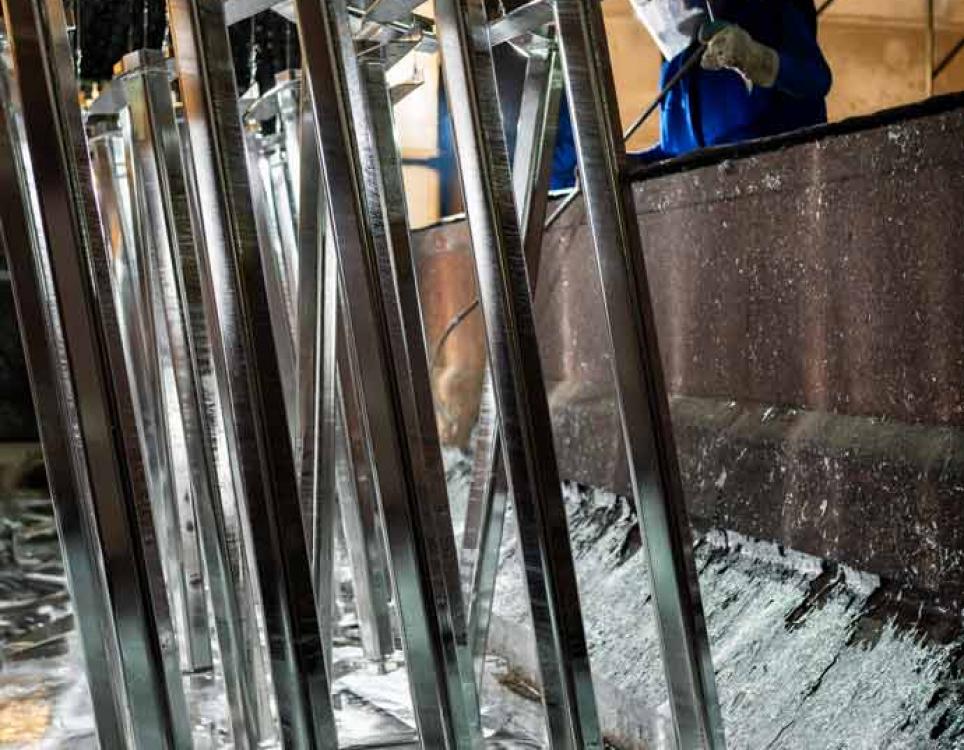

Managing industrial wastewater from surface finishing and plating operations requires the removal of heavy metals, oils, and suspended solids to meet strict environmental standards. With the steady growth of industrial manufacturing in metal finishing, discharge regulations are becoming increasingly rigorous. For over 50 years, MacDermid Envio Solutions has delivered innovative, efficient, and cost-effective systems to help operators stay compliant while maintaining a competitive edge.

Explore our Case Studies section to see how MacDermid Envio Solutions empowers surface finishing companies to optimize wastewater treatment for maximum efficiency and sustainability.

Keeping Surface Finishers Ahead

Surface finishing wastewater poses unique challenges due to its high pollutant concentration and sludge production. MacDermid Envio Solutions offers tailored metal removal solutions for businesses of all sizes, from small shops to large-scale aerospace manufacturers. Our technology supports a wide range of processes, including captive plating, phosphatizing, anodizing, chrome conversion, parts washing, vibratory deburring, E-coating, and more.

We manufacture critical system components and provide complementary chemicals to ensure seamless operation and compliance. Our industry-leading solutions enable clients to achieve long-term efficiency, meet stringent environmental requirements, and improve their bottom line.

Interested? Schedule a consultation with us today.

Efficient Sludge Management

Metal plating and surface finishing processes generate metal hydroxide sludge as a by-product. After metals and organic materials are removed during treatment, the remaining sludge must be safely disposed of, often at significant cost—especially if it contains hazardous materials.

MacDermid Envio Solutions specializes in advanced dewatering technologies that minimize sludge weight, recover valuable resources, and reduce disposal expenses. Our solutions are designed to optimize efficiency, reclaim water, and enhance sustainability in every operation.

Applications

Our expertise supports a broad range of industrial surface finishing and metalworking processes, empowering businesses to meet today’s challenges while preparing for tomorrow’s opportunities.

Industry Insights – Trusted Publications

MacDermid Envio Solutions collaborates closely with leading industry publishers and trade journals, including:

- Finishing & Coating (USA)

- Products Finishing (USA)

- Galvanotechnik (Germany)

Explore their websites for the latest industry news, trends, and technical updates. You can also discover expert insights from MES specialists in our Articles Library.