Solving Wastewater Treatment Challenges for an Electronics Manufacturer

Challenge

Complex contaminants require innovative treatment

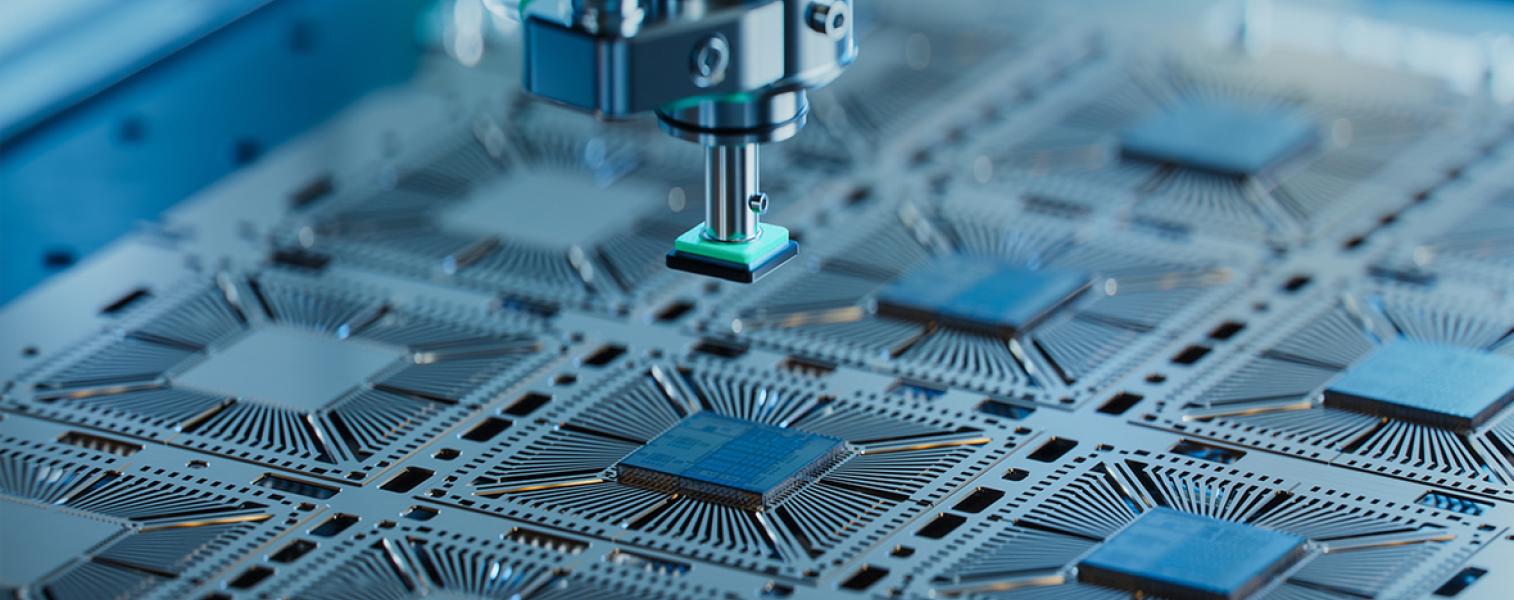

A leading electronics manufacturer, operating multiple facilities nationwide, required scalable and adaptable wastewater treatment systems to ensure compliance across diverse regions. Complex contaminants and changing production processes made wastewater treatment even more difficult.

- A variety of complex contaminants, including lead, chrome, nickel, and cyanide

- Industry-specific demands

- Facility changes over time

THE MACDERMID ENVIO SOLUTION

Flexible systems for evolving needs

MacDermid Envio created a tailored solution to meet challenges and ensure compliance.

Steps included:

- Assessing the existing system for capacity and performance

- Designing a system to treat runoff and meet regulations

- Collaborating with staff to build an adaptable solution

As operations changed, adjustments were made:

- Integrating PC board production with battery manufacturing

- Halting metal plating and expanding PC board output

- Adding a batch system for photo-resist treatment

- A remote monitoring system was installed to oversee all processes and equipment

RESULTS

Adaptable wastewater treatment ensures compliance and efficiency

MacDermid Envio delivered:

- A flexible system designed to meet the facility’s changing wastewater needs

- Enhanced monitoring capabilities without requiring a full system overhaul

- A lasting partnership committed to adapting alongside industry shifts

From installation to ongoing support, MacDermid Envio ensured every step was seamless. Explore MacDermid Envio’s wastewater solutions to discover how to cut costs, maintain compliance, and boost efficiency.