Carbonate Removal Enhances Performance

The Challenge

A German zinc-nickel plater sought to minimize electrolyte waste, embrace sustainability, and adopt advanced processes. Rising waste disposal costs and stricter environmental standards demanded a rethink of waste and wastewater management.

The challenge: Carbonates and sulfates accumulated in the ZnNi bath, compromising quality. The plater relied on the labor- and cost-intensive Bleed & Feed process to maintain deposition quality. However, this method generated excessive electrolyte waste, prompting the company to install a CarboPure unit for a more sustainable solution.

The MacDermid Envio Solution

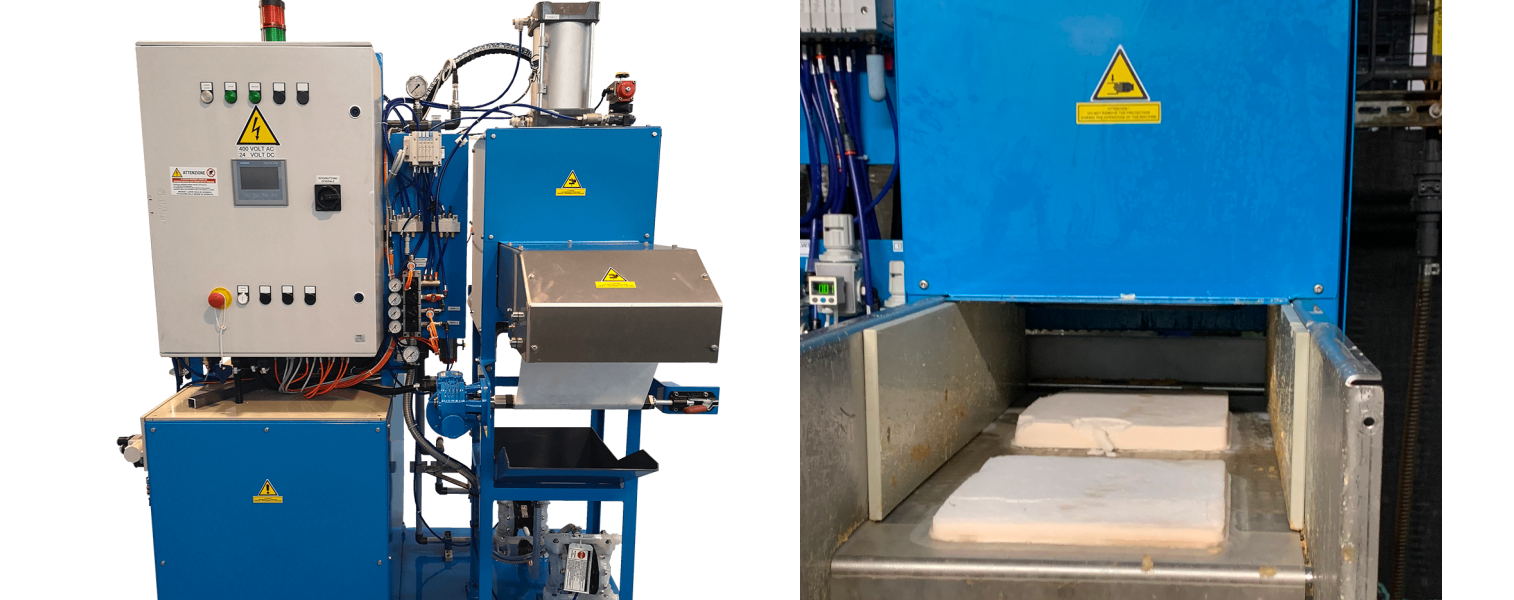

The CarboPure unit removes carbonates and sulfates from the plating electrolyte, preventing salting and ensuring consistent, optimal performance.

Results

The CarboPure system delivered:

- Reduced costs and labor

- Savings on raw materials and energy

- Enhanced environmental and energy efficiency

- Improved solution conductivity, cutting energy use by 15–20%

- Reduced zinc content, drag-out, plating time, and current density

- Increased product throughput

- Significant reduction in zinc-nickel waste requiring external treatment

This innovative solution combines sustainability, efficiency, and cost savings, setting a new standard for zinc-nickel plating operations.